ROBUST. COMPACT. INTELLIGENT.

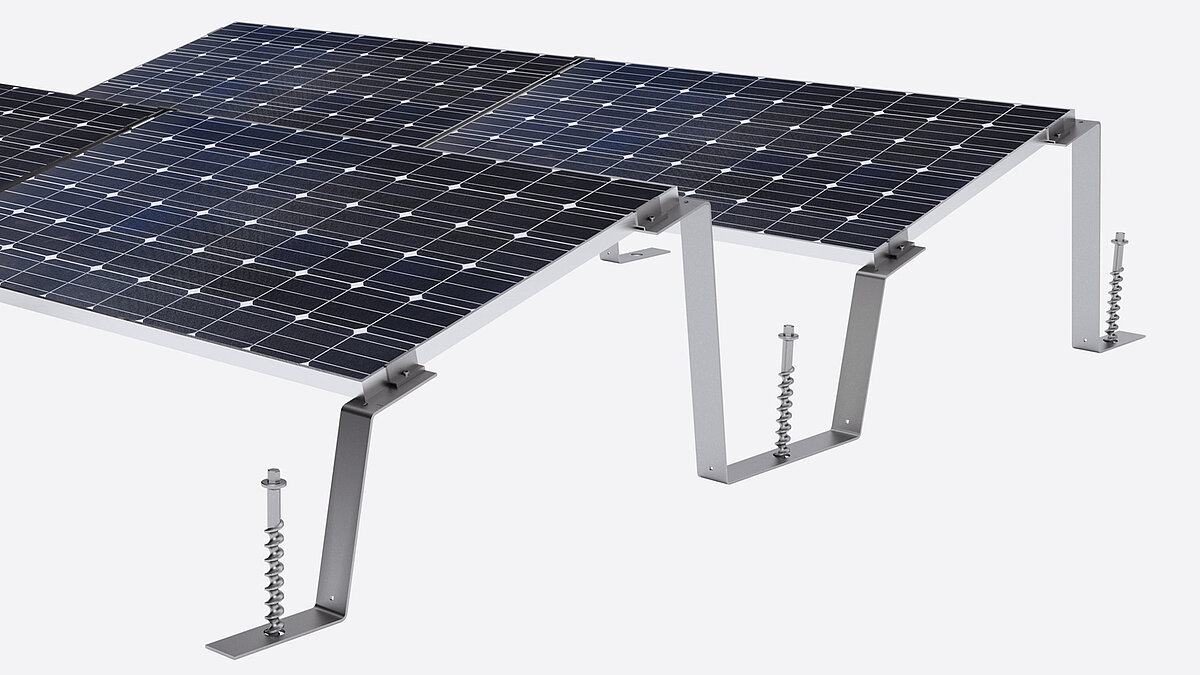

After our bracket-based system has proven and established itself on flat roofs, we have expanded the brackets for other areas of application and can thus bring the many advantages to open spaces as well. This is made possible by the unique "spring effect" of the brackets, whereby the substructure adapts optimally to the conditions of the surface.

SELECT YOUR SYSTEM

Products Total: 7

Tilt angle

Secured with

Shading angle

Alignment

G15

CompactGROUND G15 – 555 mm row spacing

- Tilt angle: 15°

- Secured with: Ballast Blocks, Gravel/River Rocks, Anchor attachment

- Shading angle: > 20°

- Alignment: South

G15

CompactGROUND G15 – 797 mm row spacing

- Tilt angle: 15°

- Secured with: Ballast Blocks, Gravel/River Rocks, Anchor attachment

- Shading angle: < 20°

- Alignment: South

G20

CompactGROUND G20 – 734 mm row spacing

- Tilt angle: 20°

- Secured with: Ballast Blocks, Gravel/River Rocks, Anchor attachment

- Shading angle: > 20°

- Alignment: South

G20

CompactGROUND G20 – 1054 mm row spacing

- Tilt angle: 20°

- Secured with: Ballast Blocks, Gravel/River Rocks, Anchor attachment

- Shading angle: < 20°

- Alignment: South

G10 PLUS

CompactGROUND G10 PLUS – 400 mm row spacing

- Tilt angle: 10°

- Secured with: Ballast Blocks, Gravel/River Rocks, Anchor attachment

- Shading angle: none

- Alignment: East/West